If any hydrocarbon (HC)/bitumen is present in a sample, additional clean-up steps may be required for preparing the sample for further analyses such as PSD, XRD, XRF, Petrography etc. Typically this is done by the Dean-Stark method.

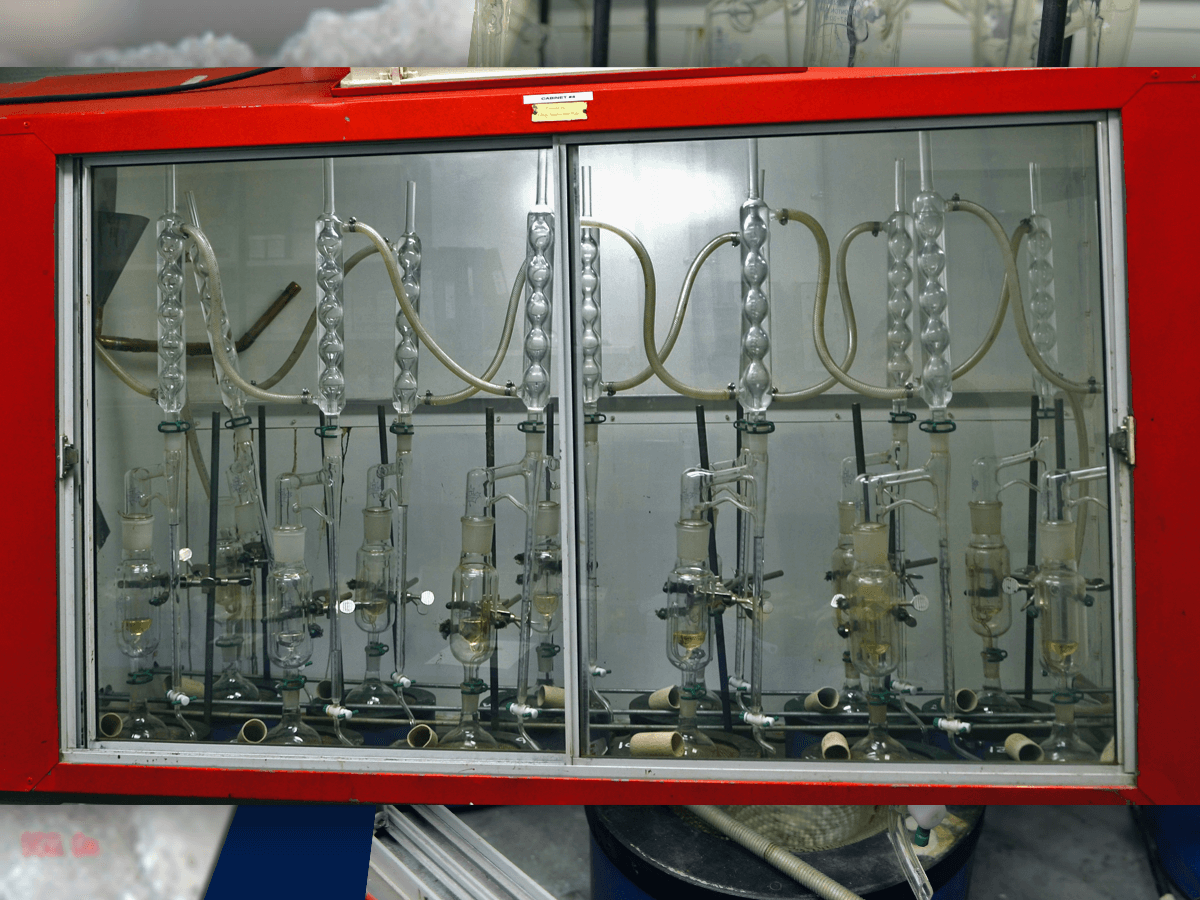

Dean-Stark is a method and apparatus used to separate and quantitatively determine the bitumen, solids, and water content of a given sample by extraction of soluble HCs with toluene in a reflux method. In this method the sample is placed in a filtering container, referred to as a thimble. Toluene is placed in a flask in the apparatus and heated to boiling so that vapors can wash the sample multiple times, thereby separating the water and bitumen from the solids. The solids (bulk + clay) remain in the thimble while the bitumen is dissolved in toluene. The water vapors condense at the top of the apparatus and are collected and measured in a burette trap. The extraction reflux is continued until the sample is clean. The solids are removed from the thimble and dried in an oven to evaporate the toluene, and are then ready for further analysis.

If extraction of the liquid HCs in the sample is required for further analysis (by this point in handling the sample the volatiles, or VOCs, will already have been evaporated), then distillation methods are used to further separate the bitumen from the toluene that has washed the solid sample.